Forum Replies Created

-

AuthorPosts

-

March 27, 2021 at 1:49 pm #36843

wristpinParticipant

wristpinParticipantI would presume that there’s a forward/ neutral /reverse shaft/lever sticking out of the hydrostatic drive unit that should be connected to a handlebar control lever.

March 21, 2021 at 11:14 pm #36825 wristpinParticipantMarch 21, 2021 at 11:44 am #36820

wristpinParticipantMarch 21, 2021 at 11:44 am #36820 wristpinParticipant

wristpinParticipantYours looks to be quite a “modern” version with a Kubota Mag engine. Not sure about the non “aspirated” version – predictive text ?

Anyway I have some Operator / parts manuals for what was then known as the Clearway HS 30” rotary grasscutter. 1973 onwards .

If these will be of any assistance I can scan them for you.March 12, 2021 at 10:19 am #36760 wristpinParticipant

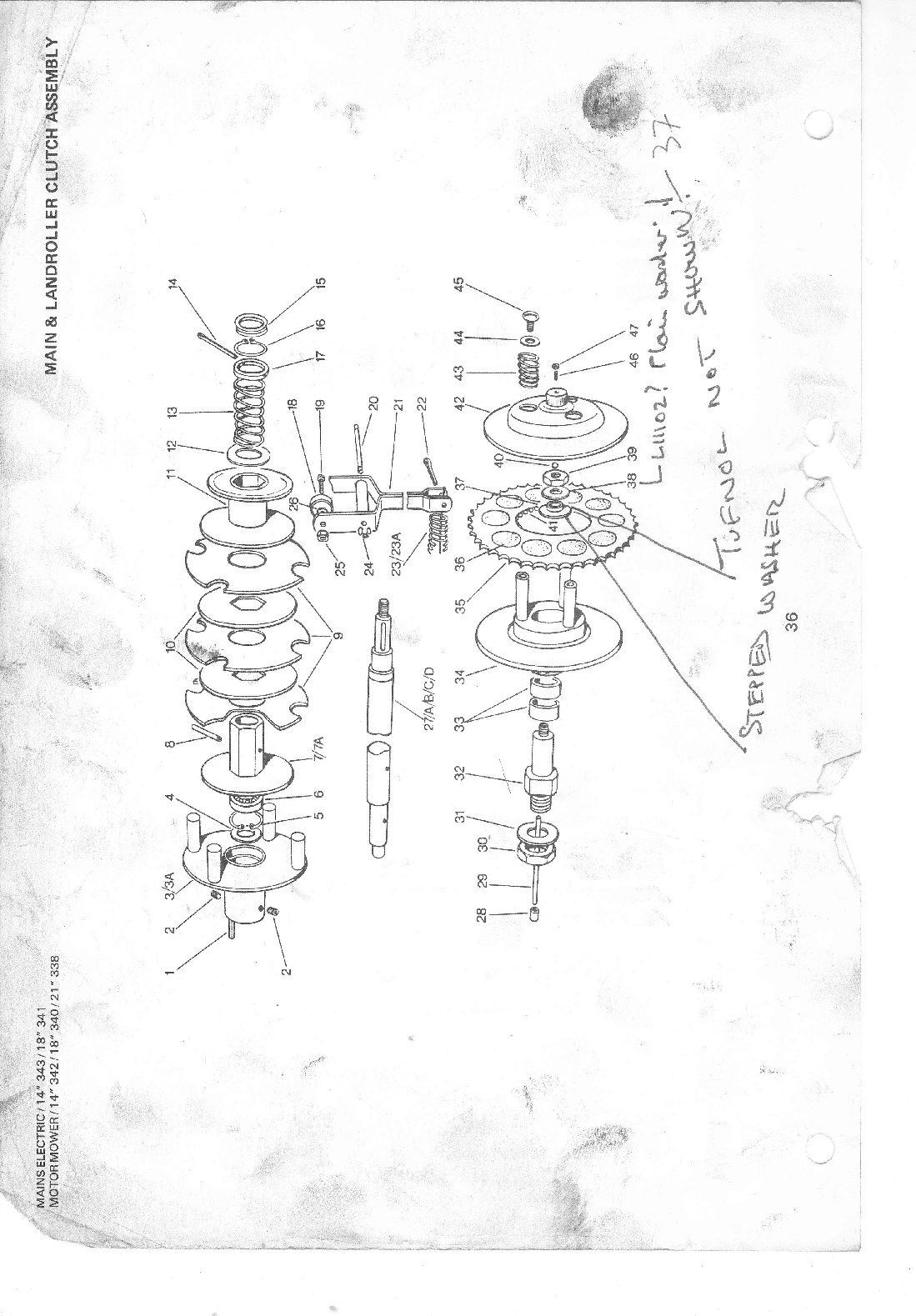

wristpinParticipantA lot easier to sort with the metal in front of one but referring to the parts illustration that I’ve already posted, try the following.

I doubt if the pin (push rod 29) is worn enough to cause your problem but remove the pressure plate (42) and push the pin right through the clutch shaft (32) taking care not to loose the ball bearing (40) – always assuming that it is not missing. If it is missing it’s probably the cause of your problem. Clean any rust and dried grease from the bore of the shaft, lubricate and reassemble the pin and ball. If the end of the pin is worn concave where it bears on the ball, just reverse it. With it all reassembled pull up and lock the handle bar clutch lever and then check that the pressure plate is releasing the sprocket(35)from the clutch body(34). If it’s not. Release the locknut (47) and screw in the adjusting grub screw (46) until it just lifts the pressure plate from the sprocket and that the sprocket is free from the body. With the handle bar clutch lever released and the pressure plate clamping onto the sprocket, there should be a little slack in the cable.

Another possible issue is that the handlebar lever locking latch is worn and although the clutch is releasing when the lever is squeezed bu hand, when your hand is released the locking latch is not holding the clutch fully disengaged.March 9, 2021 at 6:05 pm #36749 wristpinParticipantFebruary 18, 2021 at 11:41 pm #36659

wristpinParticipantFebruary 18, 2021 at 11:41 pm #36659 wristpinParticipant

wristpinParticipantIs it on a green one by any chance?

February 9, 2021 at 11:24 pm #36593 wristpinParticipant

wristpinParticipantStandard ring set, still available, £33.95 +vat retail

Chrome set, obsolete

+10 obsolete

+20 £42.15 +vat

+30 £36 +vatThe above are for genuine BS parts , you may be able to find pattern parts cheaper.

I can point you in the direction of a genuine standard set considerably cheaper than UK trade price but not on a public forum. If you are interested, get your private messaging sorted, or get adnin to send me your email address.February 9, 2021 at 6:10 pm #36590 wristpinParticipant

wristpinParticipantDefinitely says “sent” , would have expected you to have received an email Notification. Try clicking on your username or avatar, activity and then contact, messages or notification or something similar.

February 8, 2021 at 10:00 pm #36585 wristpinParticipant

wristpinParticipantYes, 25th, October 1982.

80200- 80299, 1619-1891

These are the part numbers but I don’t know about availability for all of them.

Chrome rings, std for worn bores within spec in the manual. 297201

STD rings 294232- available.

+10 oversize 294224

+20 294225

+30 294226

If I can work out how to send a private message, I will give you some info that may be useful.

Edit . Message sentFebruary 8, 2021 at 1:32 pm #36583 wristpinParticipant

wristpinParticipantTo give an accurate and informed answer we need the Model, Type and Code numbers from the engine. Usually stamped into the blower housing / cowling.

January 21, 2021 at 10:58 pm #36472 wristpinParticipant

wristpinParticipantThis is for all those Saturday mornings I worked, booking in and working on a Tesco carrier bag full of parts of a recoil starter that someone had taken apart and couldn’t get back together.

To the lady instructed to get a belt or cable for hubby’s mower.

“ yes Madam, a lot of them are green”January 19, 2021 at 5:40 pm #36455 wristpinParticipant

wristpinParticipantEasy-start – the ruin of many an engine !!

January 16, 2021 at 11:29 am #36421 wristpinParticipant

wristpinParticipantExhaust removal – my method. I’ve found that using this method from the outset rather than getting everything chewed up with Stillsons etc, usually to no avail.

Cut the old muffler off leaving about 1/2” of the stub proud of the block.

Take a 4” length of hacksaw blade in a handle or wrapped in masking tape, with the teeth pointing back to cut on the pull stroke.

Insert right into the stub and make a longitudinal cut through the wall of the stub down to the point where it’s just touching the threads in the block.

Take a set of Mole / Vice grips and grasp the stub at right angles / parallel to the block face and position one jaw along, but not overlapping the cut.

Squeeze the grips to collapse that section into the bore of the pipe.

Continue the squeeze and collapse until a good proportion of the pipe has pulled away from the internal wall of the block.

At this stage the grips can usually be repositioned to wrangle the collapsed stub out of the block.January 15, 2021 at 11:32 pm #36417 wristpinParticipantJanuary 15, 2021 at 4:42 pm #36416

wristpinParticipantJanuary 15, 2021 at 4:42 pm #36416 wristpinParticipant

wristpinParticipantFor what it’s worth, Hayter called them Twikclips pt no 2304. A quick Google is not helpful but time spent with an old Kelley’s Directory or similar may be.

-

AuthorPosts