Lawn Fertiliser Spreaders

March 25, 2024 in Articles, Machinery

You may be wondering why there’s a picture of a stuffed green frog in this article, but more about that later…

I’ve concluded that nearly every garden, certainly those with a lawn, will have felt the presence of a garden lawn fertiliser spreader at some point. In particular, one of those plastic spreaders given away if one purchased a significant amount of granular fertiliser. Several of those plastic freebie spreaders had the unfortunate ability to block up if there was even the slightest bit of moisture on the grass that got onto the distributor. But some adverts worked in reverse where the fertiliser was free when a spreader was bought; and others just offered a free loan of the spreader.

Over the decades there has been a significant number of push lawn spreaders, plastic and steel, which have promised to give the perfect amount of lawn care product to lawns. They all work on much the same principle of non-slip wheels, a hopper, some sort of regulator to distribute the goods evenly, and a handle.

Cunningly, as with most of these domestic spreaders, there was often a range of weed and feed products that also went with them (not forgetting that some of the cheaper spreaders were calibrated for their own products) – and once one had the spreader then it would be easier to keep buying that manufacturers’ products year after year and trust that the system of looking after the lawn worked….and it did work, a foolproof way to look after the lawn with ease.

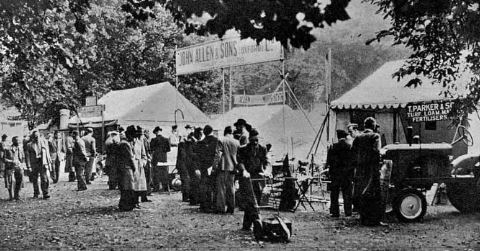

Briefly, here are a few companies that sold lawn spreaders:

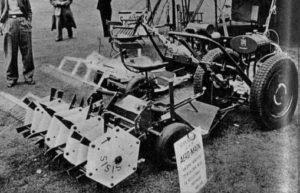

Sisis started to produce a range of their Truspred models in the early 1960s – Click for advert image. These were available in 20″, 24″, 36″ and 36″ Super, although the range was of a professional quality and often aimed at sports pitches and the like. A smaller more domestic-friendly 15″ model was advertised in the late 1960s for £8 15s. Many models were promoted for ‘accurate, consistent spreading of seed and modern fertilisers’ regardless of manufacturer. They were also good for applying lawn or surface dressings and rock salt to de-ice drives and paths in winter.

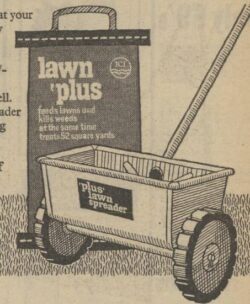

ICI promoted their ‘Plus’ Lawn Spreader in the 1970s. Often a 12″ model, it was priced at 45s in 1970, but if the gardener had signed up for the ICI Garden Savers Plan there was a 6s refund. By 1980 ICI was selling a 12″ lawn spreader for as little as £8.

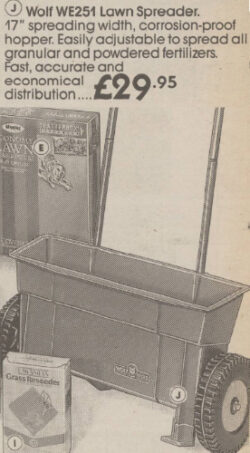

Wolf produced different spreaders in the 1970s and ’80s – Click for image. The model WE 16″ distributor had a curved metal hopper with a tough green-coloured stove enamel finish. The WE 18″ had a PVC hopper, while the WD was all steel. In the 1990s, Wolf produced the 17″ WE251 (Illustrated, below), sold in B&Q priced at £29.95.

Fisons is a popular name in the gardening game. The range of chemical products in the 1970s included the Evergreen 80 for a weed-free lawn, also Lawn Food, Lawn Peat and Velvetone Spring Dressings. Accordingly, Fisons also had a lawn spreader, sometimes in a blue paint scheme – Click for Image. But they also had a budget 12″ spreader advertised in 1970 for only 35s when bought with a combined purchase of Evergreen 80 and Fisons Rose Food – an odd combination but maybe the rose food wasn’t a big seller?

PBI had lawn spreaders through the 1980s, but they could also come coupled with a product. In 1989 the spreader came with a free pack of their Toplawn 600sq feet pack of Weed & Feed for £16.

In the 1990s both Levingtons and Scotts spreaders appear in advertising. Scotts models being the Accugreen and Evergreen. And today, a vast range of spreaders with different branding are marketed.

And what about the stuffed green frog shown at the top of this article? Well, who remembers the Fisons Evergreen TV adverts from perhaps 20 years ago, with a cartoon gangly-legged frog sprinkling some lawn feed around? I think the song went ‘If the lawn is a farce, and the weeds a right pain in the grass….‘. I bought some lawn feed, got a free lawn spreader (which is gathering spiders and dust in the back of the barn), also filled in and sent off a form, and amazingly this stuffed Fisons Evergreen frog turned up in the post – forget expensive vintage sales merchandise and paraphernalia because I’ve got a stuffed green Fisons frog…now that’s proper advertising!

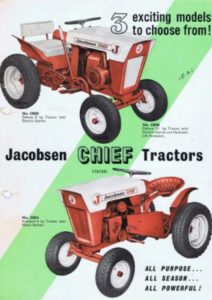

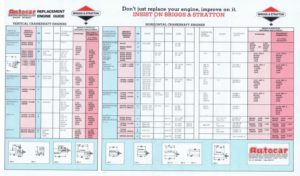

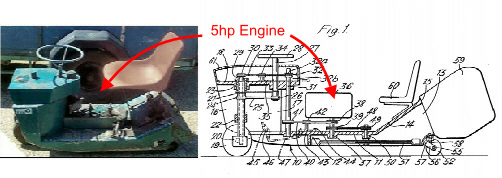

Sometimes it’s necessary to change the engine on a machine, usually this is because the existing one, often the original, has come to the end of it’s life and parts are no longer available or it’s just not cost effective. A new replacement engine is the obvious choice and there’s many brands to choose from including the ‘knock-off’ copies of many. Also as important is if the machine in question; a garden tractor, ride-on mower, lawnmower, tiller, etc is required to still look the part and have an age-related engine rather than new in which case a second-hand engine is an option.

Sometimes it’s necessary to change the engine on a machine, usually this is because the existing one, often the original, has come to the end of it’s life and parts are no longer available or it’s just not cost effective. A new replacement engine is the obvious choice and there’s many brands to choose from including the ‘knock-off’ copies of many. Also as important is if the machine in question; a garden tractor, ride-on mower, lawnmower, tiller, etc is required to still look the part and have an age-related engine rather than new in which case a second-hand engine is an option.

….The reason is that Webb make several subliminal references to expense which may not go down too well with the person who controls the purse strings. Webbs advice is to “Go for the best you can afford” and “Webb recommended prices allow your dealer to provide….guidance, instruction, preparation and service requirements” i.e this ain’t gonna be cheap. In the picture on the right we see the Webb mower being invited to afternoon tea and admired by it’s new owners – it’s not just a new mower but a piece of one-upmanship over the entire neighbourhood and their new-fangled Flymos. The Webb is something to aspire to.

….The reason is that Webb make several subliminal references to expense which may not go down too well with the person who controls the purse strings. Webbs advice is to “Go for the best you can afford” and “Webb recommended prices allow your dealer to provide….guidance, instruction, preparation and service requirements” i.e this ain’t gonna be cheap. In the picture on the right we see the Webb mower being invited to afternoon tea and admired by it’s new owners – it’s not just a new mower but a piece of one-upmanship over the entire neighbourhood and their new-fangled Flymos. The Webb is something to aspire to.  Let us visit some old technology which is now new technology that hasn’t progressed much from the old technology and get ourselves a battery mower to cut down on the use of petrol. The largest 18″ deluxe model which is the left mower in the picture was £132.00 in 1973, approx 30% more than the petrol version. The smallest model was a 12″ cut and priced £54.95 (prices inc tax).

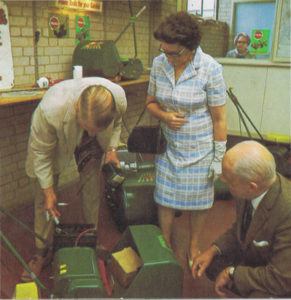

Let us visit some old technology which is now new technology that hasn’t progressed much from the old technology and get ourselves a battery mower to cut down on the use of petrol. The largest 18″ deluxe model which is the left mower in the picture was £132.00 in 1973, approx 30% more than the petrol version. The smallest model was a 12″ cut and priced £54.95 (prices inc tax). The next models are the petrol powered stuff, this is where one can be accused of wanting a mower purely because it has an engine. As can be seen in the image the gentleman has been accompanied to the dealership to ensure money isn’t squandered on unnecessary and frivolous purchases, honestly, as if anyone would buy stuff on a whim to hoard in the shed. Besides, there’s a really scary receptionist lurking in the background to keep things in order.

The next models are the petrol powered stuff, this is where one can be accused of wanting a mower purely because it has an engine. As can be seen in the image the gentleman has been accompanied to the dealership to ensure money isn’t squandered on unnecessary and frivolous purchases, honestly, as if anyone would buy stuff on a whim to hoard in the shed. Besides, there’s a really scary receptionist lurking in the background to keep things in order.

For utter devilment our gentleman in the dealership image could be forced by his female companion to have a hand-push mower, that’d teach him to look out of the kitchen window and daydream for a petrol powered machine instead of getting on with doing the washing-up at home. The push mower range consisted of the 10″ Whippet, 12″ Wasp and 12″ Witch. Respectively priced at £17.54, £18.64 and £25.24 inc tax.

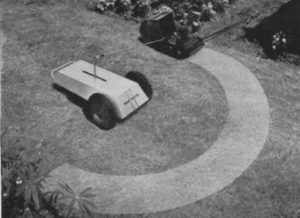

For utter devilment our gentleman in the dealership image could be forced by his female companion to have a hand-push mower, that’d teach him to look out of the kitchen window and daydream for a petrol powered machine instead of getting on with doing the washing-up at home. The push mower range consisted of the 10″ Whippet, 12″ Wasp and 12″ Witch. Respectively priced at £17.54, £18.64 and £25.24 inc tax.  Once the lawn is cut then it’s time to do the edges and Webb come to the rescue with a battery-operated lawn edger. This talented machine has a 6 volt battery that can trim for about 45 minutes – about 1200 yards of lawn edges. It has a 7″ blade that revolves at 5000 rpm giving about 10,000 cuts per minute. Apparently it can trim lawn edges better than they have ever been trimmed before – I think some professionally trained groundsman might have disagreed with that statement but they probably agree that it was a lot easier than using long-handled shears.

Once the lawn is cut then it’s time to do the edges and Webb come to the rescue with a battery-operated lawn edger. This talented machine has a 6 volt battery that can trim for about 45 minutes – about 1200 yards of lawn edges. It has a 7″ blade that revolves at 5000 rpm giving about 10,000 cuts per minute. Apparently it can trim lawn edges better than they have ever been trimmed before – I think some professionally trained groundsman might have disagreed with that statement but they probably agree that it was a lot easier than using long-handled shears.