Ryan and Horwool turf equipment

April 14, 2017 in Articles, Machinery

We probably all know the name of Horwool and their ride-on triplex mowers and the Landscaper 1200 tractor – see them in the Horwool gallery. In the 1960’s Horwool, based in Romford, were also the agents for the American built Ryan turf equipment which was shipped over to the UK.

Ryan still make lawn care equipment ( https://www.ryanturf.com/about-ryan/ ). The most interesting piece of equipment from the 1960’s being the range of turf cutters that cut the rolls of turf that are laid for new lawns. These machines have knobs and levers and many moving parts and would probably make a fascinating horticultural exhibit at a show although I doubt we’d be allowed to strip the showfield at Newark Tractor Show as an attraction – but it’d draw the crowds.

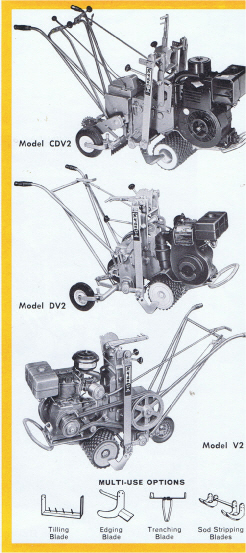

The 1960’s machines seem to differ very little from their modern day equivalents. The turf cutters pictured right, from the 1965 brochure, were capable of cutting three acres of turf per day per machine, that’s just under 15,000 square yards. The machines automatically cut-off the turf at the correct length and had different types of blades for varying turf conditions.

Powered by 7hp Wisconsin engines or 9hp Briggs and Stratton engines on the larger machines, they had a disc clutch and disc brake for the automatic turf cut-off.

The only down-side I can see is that there still needed to be a man on his knees rolling up the turf behind the operator and stacking it on pallets. The brochure does show that the turf can be either rolled up or laid flat on pallets.

Has anyone got an old UK Ryan turf cutter? I’m sure that there will still be some in use today as they would be well looked after if they were heavily relied upon.

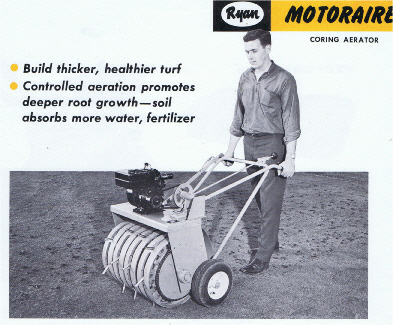

Ryan also produced the Motoraire, pictured below, which much like Sisis machines “removes cores of soil to open up the soil and let air, moisture and fertilizer down into the grass root zone” . Ryan add that “Aeration with a Ryan Motoraire should be used for maintaining healthy turf and for rebuilding and rejuvenating turf of poorer quality“.

Powered by what appears to be a Briggs and Stratton engine rated at 3hp, Ryan recommend the Motoraire for “beautifying school playgrounds, athletic fields, hospitals and industrial plant grounds and home lawns, it is also highly recommended for…use by landscapers, lawn maintenance companies, rental companies and nurseries“.

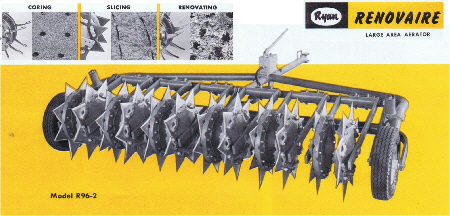

Ryan machines were not just limited to walk-behind machines, there’s also the tractor mounted Renovaire. This machine, image below from 1964, could do coring, slicing and renovating of turf and was “designed for fast, economical aerating of large turf areas” such as golf courses, sports pitches and parks.

The operating speed when working is up to 10mph and when not working the 8′ wide machine can be transported on it’s 4.00 x 8″ pneumatic tyres behind a truck or car at reasonable driving speed on a field or site.

Horwool also had some of their own turf equipment. There is the Powarake, and also the Powaroll, both great names.

The Powarake, pictured below left, was a 3 1/2 hp, BSA powered lawn de-thatcher. With a centrifugal clutch it had 100 self-cleaning flexible steel tines and mechanically lifts thatch and debris from the lawn. Apparently tree roots, curbs and stones will not damage the tines which run at 1200 RPM.

The Powaroll, pictured below right, had a 3hp Briggs and Stratton engine and featured reverse for maneuvering in tight spaces. When the roller was filled with water it weighed in excess of a quarter of a ton which gave effective levelling and compaction of the ground.

For reference and anyone researching Horwool, the address on the brochures is:

Horwool (Manufacturing ) LTD

Upper Bedfords

Lower Bedfords Road,

Romford,

Essex,

England.

Ryan still make lawn care equipment ( https://www.ryanturf.com/about-ryan/ ). The most interesting piece of equipment from the 1960’s being the range of turf cutters that cut the rolls of turf that are laid for new lawns. These machines have knobs and levers and many moving parts and would probably make a fascinating horticultural exhibit at a show although I doubt we’d be allowed to strip the showfield at Newark Tractor Show as an attraction – but it’d draw the crowds.

The 1960’s machines seem to differ very little from their modern day equivalents. The turf cutters pictured right, from the 1965 brochure, were capable of cutting three acres of turf per day per machine, that’s just under 15,000 square yards. The machines automatically cut-off the turf at the correct length and had different types of blades for varying turf conditions.

Powered by 7hp Wisconsin engines or 9hp Briggs and Stratton engines on the larger machines, they had a disc clutch and disc brake for the automatic turf cut-off.

The only down-side I can see is that there still needed to be a man on his knees rolling up the turf behind the operator and stacking it on pallets. The brochure does show that the turf can be either rolled up or laid flat on pallets.

Has anyone got an old UK Ryan turf cutter? I’m sure that there will still be some in use today as they would be well looked after if they were heavily relied upon.

Ryan also produced the Motoraire, pictured below, which much like Sisis machines “removes cores of soil to open up the soil and let air, moisture and fertilizer down into the grass root zone” . Ryan add that “Aeration with a Ryan Motoraire should be used for maintaining healthy turf and for rebuilding and rejuvenating turf of poorer quality“.

Powered by what appears to be a Briggs and Stratton engine rated at 3hp, Ryan recommend the Motoraire for “beautifying school playgrounds, athletic fields, hospitals and industrial plant grounds and home lawns, it is also highly recommended for…use by landscapers, lawn maintenance companies, rental companies and nurseries“.

Ryan machines were not just limited to walk-behind machines, there’s also the tractor mounted Renovaire. This machine, image below from 1964, could do coring, slicing and renovating of turf and was “designed for fast, economical aerating of large turf areas” such as golf courses, sports pitches and parks.

The operating speed when working is up to 10mph and when not working the 8′ wide machine can be transported on it’s 4.00 x 8″ pneumatic tyres behind a truck or car at reasonable driving speed on a field or site.

Horwool also had some of their own turf equipment. There is the Powarake, and also the Powaroll, both great names.

The Powarake, pictured below left, was a 3 1/2 hp, BSA powered lawn de-thatcher. With a centrifugal clutch it had 100 self-cleaning flexible steel tines and mechanically lifts thatch and debris from the lawn. Apparently tree roots, curbs and stones will not damage the tines which run at 1200 RPM.

The Powaroll, pictured below right, had a 3hp Briggs and Stratton engine and featured reverse for maneuvering in tight spaces. When the roller was filled with water it weighed in excess of a quarter of a ton which gave effective levelling and compaction of the ground.

For reference and anyone researching Horwool, the address on the brochures is:

Horwool (Manufacturing ) LTD

Upper Bedfords

Lower Bedfords Road,

Romford,

Essex,

England.