Charlie Moore (aka charlie)

@charlie Active 7 hours, 21 minutes agoForum Replies Created

-

AuthorPosts

-

March 24, 2014 at 4:44 pm #6851

charlieKeymaster

charlieKeymasterOpps, just re-read title and see it is a series 1.

March 24, 2014 at 4:43 pm #6850 charlieKeymaster

charlieKeymasterSwampy, my first question is which model of Monro Tiller? See my website for details of how to identify which you have. I have owners manuals with parts list for all models. I may also be able to help with spares (second hand from scrap machine). Any good bearing supplier should be able to supply bearings. Any photos of machine and damaged parts?

March 24, 2014 at 4:38 pm #6848 charlieKeymasterMarch 23, 2014 at 7:50 am #6807

charlieKeymasterMarch 23, 2014 at 7:50 am #6807 charlieKeymaster

charlieKeymasterAlan, it probably won’t be as long as my SIMAR M11 restoration which is approaching the 9 year mark!

March 23, 2014 at 7:48 am #6806 charlieKeymaster

charlieKeymasterWonder if Mr Wallingfield will be attending?

March 23, 2014 at 7:36 am #6805 charlieKeymaster

charlieKeymasterAngus, we did try to get members to use their real names but this did not work. The idea of the free trial is to give users a chance to see what is available and hopefully realise what a good club we are and join.

Unfortunately we do get the occasional spammer, we are working on improving the anti spam measures, but the spammers are also working on ways around them.March 22, 2014 at 6:11 pm #6791 charlieKeymaster

charlieKeymasterTo make some sort of progress I took the fuel tank and side panels to Tractor World in 2013 to deliver them to EFL Panels so they could make new ones. Tractor World 2014 and the new fuel tank was collected. First two photos show old fuel tank and side panels, last photo shows old and new tanks.

March 22, 2014 at 6:05 pm #6788 charlieKeymaster

charlieKeymasterProgress now hit another snag. Due to the time taken so far, my eldest son had now left school, stared work and had his own Land Rover which he was rebuilding. This caused another delay as there was not room for both of us to work in the garage. Before and after photos of Alex’s Land Rover, note headlights removed in after photo to avoid damage whilst trialling. Rebuild involved new chassis, rebuilt bulkhead, all bodywork rebuilt on box section frame, 3.5 V8 engine and auto gearbox, winch and roll cage. He also custom built the dashboard and installed a Range Rover heater.

March 22, 2014 at 5:52 pm #6785 charlieKeymasterMarch 22, 2014 at 5:48 pm #6779

charlieKeymasterMarch 22, 2014 at 5:48 pm #6779 charlieKeymaster

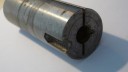

charlieKeymasterThis is what was left of the big end bearing and damage it had caused to crank pin. The photo of the crank pin shows where the locating dowel goes and how the end of the crank pin is split, another dowel goes in the end to open the split and lock the whole lot to the crank web. This proved to be a bit of a challenge to remove as only a small diameter drift could be used which had a tendency to bend.

Due to workload and my saying the job was not urgent it took a while before I was able to collect the engine but it was well worth the wait. A crack in the water jacket also had to be repaired, luckily it was only the outer and had not damaged the bore. Photos of the parts at Cox & Turner awaiting reassembly.March 22, 2014 at 5:32 pm #6778 charlieKeymaster

charlieKeymasterWhen I pulled the engine apart I found why it would not rotate fully, the big end roller bearing had broken up. This was not going to be an easy fix. Unsure of where to take the engine I phoned Cox & Turner and after a good chat with Ian Cox he confirmed they could do the work. So the engine was taken to them for a new big end bearing to be made, new crank seals fitted and magneto rebuilt by someone they knew. They were unable to get any seals that would fit the crank and crankcase so it was agreed the case would be machined to enable new seals to be fitted. A new roller bearing had to be made to order for the big end. Yes all this did cost a fair bit.

March 22, 2014 at 5:24 pm #6775 charlieKeymaster

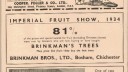

charlieKeymasterI had initially thought this was a M10 Rototiller although the air cleaner did not look right and the only photo I had seen was in the booklet ‘Experiences of Rototillage’. A trawl through the very good SIMAR website, motoculteur-simar confirmed my suspicions and I was able to identify it as an M11. Photo’s below courtesy of the website mentioned.

March 22, 2014 at 5:15 pm #6774 charlieKeymaster

charlieKeymasterStripping the clutch, which is a cone clutch, revealed a new lining would be required. This was carried out by a clutch and brake relining company, not cheap, but a very necessary job. Little did I know just how much more this restoration was going to cost!!

March 22, 2014 at 5:13 pm #6770 charlieKeymaster

charlieKeymasterThis was about as far as I got in 2005.

Major problems identified, fuel tank rotted out, tin work around rotors almost non existent, engine side covers rusted through in places and hinges broken. Handle bar adjustment to swing left or right seized solid and something certainly not right with big end of engine as it would only rotate so far. Magneto would need a full rebuild and radiator was an unknown regarding leaks. I took the radiator away to have it tested and was very pleased to find it was OK.

After much heating, soaking with penetrating oil, gentle taps with soft hammer the handle bar adjuster sleeve was still firmly stuck. I decided a bit more persuasion was needed so using a flat ended bit in the SDS drill set to hammer only I attacked the sleeve. Holding the drill against one end of the sleeve a gentle plume of smoke like rust emerged from the other end, something was happening! Further application of the drill to both ends alternating between them and eventually there was movement, success.

The next job was to tackle the engine and clutch. It was now January 2006.March 22, 2014 at 5:00 pm #6768 charlieKeymaster

charlieKeymaster -

AuthorPosts