Build a DIY Tractor

May 17, 2020 in Articles

There are plans for many machines, including this petrol-powered shredder in 1966

I’ve also found a book from 1951 which looks like it could be of use….

….But before getting excited about sticking mechanical parts together in some sort of over sized Meccano kit experiment, lets scrutinize carefully the advice given decades ago about concocting a tractor from bits…

1: The 1951 book advises that the parts required may actually be a greater cost than buying a second hand machine, it quotes that a home made four wheel machine should cost no more than £25.0.0 and a two wheel machine about £5.0.0. Considering that at the time a new two wheel Farmers Boy started around £58 and a Gunsmith about £178, a considerable saving could be made.

2: Spare parts may not be available in the future for the parts that the home made machine is compiled from. It was advised that it would be prudent to keep a stash of spares for when (not if) the home made machine breaks down. A spare engine and gearbox was suggested.

3: The home made machine may not (probably not) have the equipment and devices to keep the operator safe, like guards and easily accessible controls. This is referred to nowadays as an accident waiting to happen.

Having satisfied ourselves that the project may be possible, we next need to have a suitable workshop. I’m reminded of a family story where a young person in the 60’s decided to overhaul his motorbike. Having nowhere suitable he decided the spare bedroom would be a solution. Revving the engine and attempting to drive upstairs was not a happy outcome when, in cartoon fashion, the stair carpet was ripped from it’s mountings whilst the motorbike remained at the foot of the stairs. The calamities did not end there as the eventually bedroom’ed motorbike was treated to a through clean, the result being spilled oil and petrol seeping through to the ceiling below. Outdoor space is therefore advised, plenty of room being a must for the intended project, unlike a long ago neighbour who had to remove the end of his garage in order to extract the trailer he had made.

Just like a cookery book, the 1951 book gives a list of ingredients but in mechanical form, yet doesn’t divulge any way of attaching one to another.

But if we want to jump in at the deep end and proceed with our 1951 book and muddle a machine together in an ad-hoc manner then it recommends the following parts for a four-wheel tractor, but no instructions:

An engine (7hp), gearbox, clutch, radiator, steering (modified), front axle (inverted), and a shortened chassis (4′ 8″) all from an Austin 7. A rear axle and differential from a Wolseley Hornet, 19″ rear wheels from a Trojan, and two 8″ wheel barrow wheels for the front. This would create a 6′ 5″ long tractor.

A two-wheel tractor would again require scavenging parts from an Austin 7, these would be the engine, gearbox and clutch. The chassis would be home-made from angle-iron. The wheels would be 19″. This would give an 8′ long by 3′ wide machine.

Without plans this may turn out to be a big challenge, but help is at hand to help us achieve a home-made machine, at least in the USA anyway….

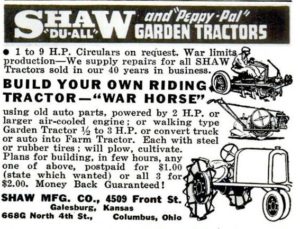

1944 Shaw tractor advert

The Shaw MFG. Co. of Kansas (image on the right) were offering plans for their tractors at $1 in 1944. This was due to the war limiting production of their own machines and therefore you could follow their plans and build your own using old car parts, and powered by a 3hp Briggs and Stratton engine. A two wheel garden tractor that was powered by a 1/2hp to 3hp engine could also be made. Apparently a machine could be constructed in a few hours, that is if the parts were readily available.

Build your own battery lawnmower in 1947

We could also make something even more amazing like the tracked Mini-Dozer or Mini-Beep lawn tractor in the style of a Jeep from Struck in the USA in the 1960’s. I know I’ve caught several peoples attention with the Mini-Beep pictured in the advert, below!

The Mini-Beep was a 4/5 scale, DIY kit of a WWII Willy’s Jeep. It was made out of plywood and had a mechanical 2wd or 4wd system. More impressive is that the Mini-Beep plans are still available to buy from the company today and the Mini-Dozer is available in kit form, too. The Mini-Beep would be a great project to undertake, especially as it can be fitted with a dozer blade or have a trailed mower for cutting the paddocks. Without a doubt, for me, I’d end up with a superior result rather than hacking an old Austin 7 to pieces!

Note: Images/media are used for research/illustration purposes for non-profit only with copyright held by respective publishers where and as applicable.