Home › Forums › Groundcare Machinery › Grass Cutting Machinery › Ransomes Motor Triple Mk4 Clutch

- This topic has 19 replies, 3 voices, and was last updated 11 months, 2 weeks ago by

smithyb.

-

AuthorPosts

-

July 22, 2022 at 11:33 am #39500

smithyb

ParticipantHi Folks,

I have a Ransomes Motor Triple Mk4, I’ve had it about 3 years and I really enjoy using it and working on it. I am no mechanic but so far I have found it reasonably easy to work on.

A problem started this week when I was cutting the lawn. For no apparent reason the clutch would not disengage when on idle. No familiar “ding ding ding” sound and the cylinders would not stop rotating as would normally happen. I had to pull it out of gear to stop.

I am hoping that it might be a broken spring or two in the clutch which is stopping the clutch from disengaging however my problem is I can’t get the clutch plate off.

I have taken off the 2 stud nuts and the central bolt and I assumed the plate would slide off with a bit of encouragement. I connected a puller to the plate which is what I assume the 2 threaded holes are for and pulled against the center where the bolt was, but it didn’t budge. I have spent a few hours at it now and I just can’t figure it out.

The attached photo shows how it is now.

I would appreciate any information on how to get the plate off.

The grass needs to be cut again and it’s just not as much fun on the 2 year old Honda!

Thanks in advance.

July 22, 2022 at 12:38 pm #39502 wristpinParticipant

wristpinParticipantThe last time I worked on an MT was about 40 years ago, but I think that you are on the right track. The drum may need a bit more persuasion.

However, there is someone on this forum, Trusty220, who may be able to impart practical knowledge.July 22, 2022 at 3:44 pm #39504 wristpinParticipantJuly 22, 2022 at 6:15 pm #39507

wristpinParticipantJuly 22, 2022 at 6:15 pm #39507smithyb

ParticipantThank you for your reply wristpin and for the manual.

I’m going to have another go at it this evening. Additional persuasion is probably what is required, it probably hasn’t been off in 20 years, if ever.

Getting the plate off will be a victory in itself irrespective of what’s going on behind it.

Thanks again, I’ll update when I make progress.

July 22, 2022 at 6:20 pm #39508 trusty220Keymaster

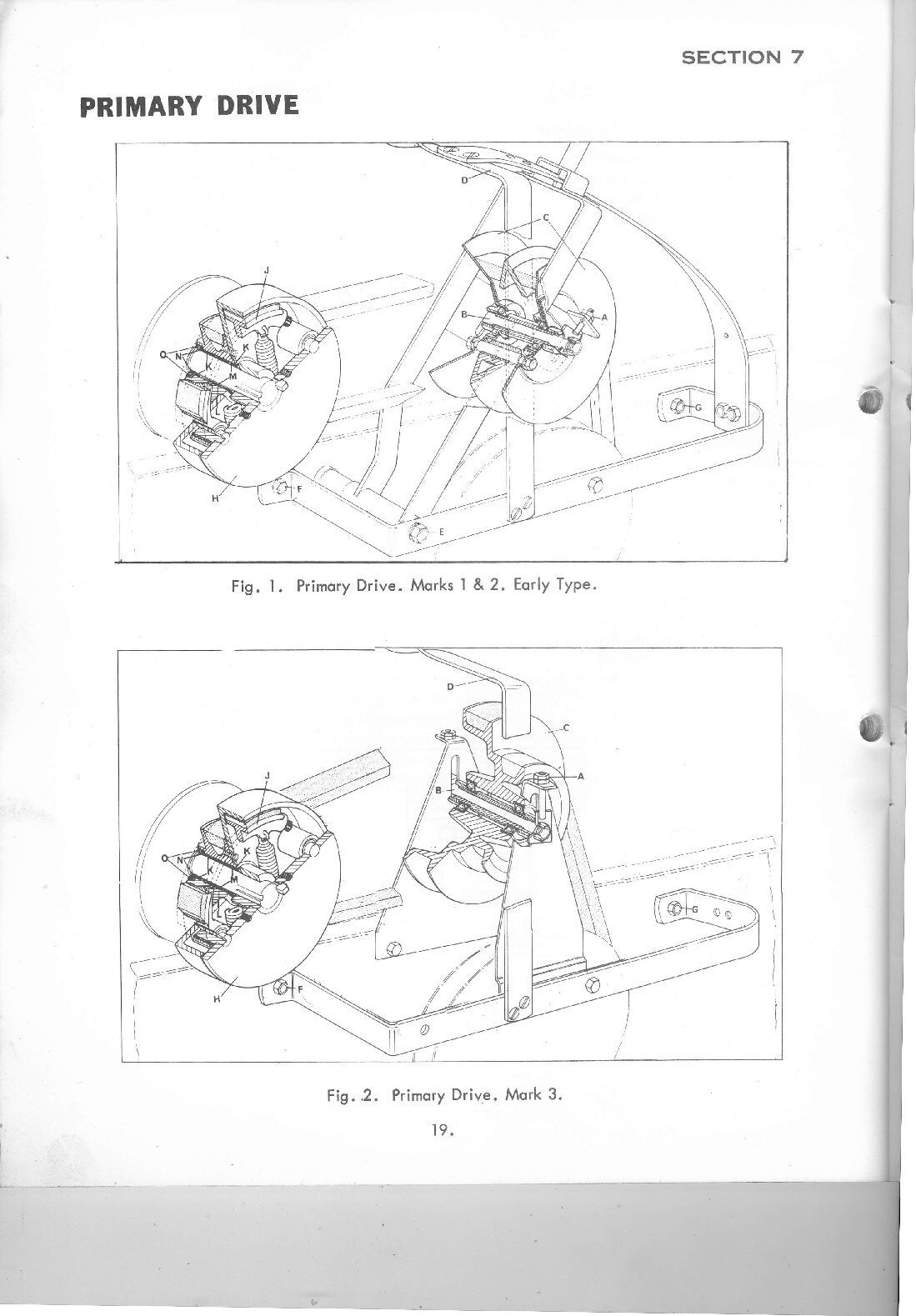

trusty220KeymasterIt will definitely be something amiss inside the main drive clutch. The two large nuts that you’ve removed hold the shoe pivot posts to the backplate and did not need to come off- they stay attached at all times.

There used to be a special tool supplied by Ransomes for removing the drive clutch. You can make one quite easily- it was 1″ thick steel bar, about 2″ wide with three holes drilled through it. The centre one was tapped for (I think) 1/2″ UNF with a long-ish bolt through it, the outer two holes were plain with no thread but drilled for a clearance to allow two 3/8″ bolts to pass through. The two threaded holes in the clutch backplate are tapped 3/8″ UNF, so you need two bolts long enough to pass through the puller and give at least eight complete turns through the backplate. All you do then is to take the centre bolt out, remove all of the washers and re-insert it to give something for the puller to push against. It should then be a simple matter of winding the 3/8″ bolts in, then tensioning the centre bolt to withdraw the clutch evenly. I’ve never had to hit it with a hammer to release it but there’s always a first time!

What you are most likely to find inside is one broken return spring out of the pair. The part number is MBA3474 and you really need to replace them in matched pairs. If you put one new one in and leave the old one in place you will find that the clutch will not engage evenly and you run the risk of having the old spring break in the same way that the first one has!

When refitting the shoes pay attention to the direction of rotation- centrifugal clutch shoes should always be fitted in a trailing position, that is with the fixed end leading and the floating end trailing. This is to allow the shoes to disengage when the revs drop; if you fit them the wrong way around (as you would in a drum brake) they will drive and they will “bite” but they won’t disengage.

I doubt that Ransomes dealers will have the parts you need but try Bartrums Mowers, I think they bought all of the Ransomes stock of Motor Triple parts when they had a clear out.

Let us know how you get on.

July 23, 2022 at 6:45 am #39511 wristpinParticipant

wristpinParticipantI doubt that Ransomes dealers will have the parts you need but try Bartrums Mowers, I think they bought all of the Ransomes stock of Motor Triple parts when they had a clear out.

There you have it from a man who’s done it !

Bartrams are now part of the Ernest Doe empire . Two other maybes for MT parts are Martyn Channer, 01494 712145 who can be found on eBay and Facebook, and Upsons 01621 892907. Check those numbers as they are from an old “ black book” !July 24, 2022 at 9:32 am #39512smithyb

ParticipantThanks so much for the detailed message trusty220. Nothing beats hands on experience.

Apart from removing the two stud nuts, I think I was heading in the right direction but just to be sure, would you mind having a look at the attached photo and let me know if this is the set up you were describing.

I refitted the 2 stud nuts, attached the puller and started to wind it on using the partially threaded central bolt to push against. The socket is being used as a spacer to avoid the studs.

The 50mm box section puller is starting to bend under pressure but the clutch has not moved. I will fit another socket or similar in to the box section for additional strength.

I think I’m almost there and if the puller set up is correct I’ll keep going and hopefully it will let go.

July 24, 2022 at 12:32 pm #39514 trusty220Keymaster

trusty220KeymasterA slightly different way of doing the same job but it should work. You are definitely on the right track; if it still doesn’t move you may want to give the central bolt a smack or two with a copper mallet to try to get it started, but it’s important that you draw the plate off evenly otherwise it will bind on the crankshaft.

If it’s still tight and refusing to move, have you tried knocking it the other way (i.e. towards the engine)? If it’s rusted on that might just do the job.

Keep going and good luck!

P.S. Thanks, Angus, for the updates on who owns what down that part of the country- as you can probably guess, I’m a little out of date! I’m sure Ernest Doe’s will be able to source the part.

July 24, 2022 at 12:54 pm #39515 wristpinParticipant

wristpinParticipantIf it’s still tight and refusing to move, have you tried knocking it the other way (i.e. towards the engine)? If it’s rusted on that might just do the job.

An inward smack may break the rust bond to get things moving. An old socket or a bit of your box section, end on will concentrate the smack close to the shaft. Also, turn the crank to position the key way to 12 o’clock and squirt a bit of proper penetrating fluid into it, in the hope that it may creep along the key and around the shaft. I say proper penetrating fluid, such as Plus Gas, rather than just a general maintenance spray.

-

This reply was modified 2 years, 11 months ago by

wristpin.

wristpin.

July 24, 2022 at 7:33 pm #39517 trusty220Keymaster

trusty220KeymasterThe only thing I could add to Angus’s suggestions are to make a more rigid bar so that you can get more pressure on the faceplate. PlusGas should get it moving but I’ve never had one that has been this stubborn, they normally pull off quite easily if you give it a straight pull.

What part of the country are you in?

July 25, 2022 at 1:56 pm #39518smithyb

ParticipantThanks for the encouragement, I finally got it off but it fought me right to the end.

I got another socket snug inside the box section so that made the puller a lot stronger.

To finally get it moving I had to put a flat head screwdriver at 12, 3, 6 & 9 O’Clock to separate the plate slightly. Then thread the central bolt back in and smack it a good 10 times. It moved a few mm from the hammering. After that, screwdrivers out and puller reattached and it started to creep off.

The shaft has a small bit of corrosion but nothing that should have made it such a struggle. It will get a good clean and grease before going back on.

I can see two problems with the clutch. The right hand spring is very loose and both springs will need to be replaced. Also, the lining (if that’s what it’s called) has worn/corroded/broken.

I’m inclined to think the spring is what was causing the problem and not the lining. There were no broken bits of lining inside so I don’t think it’s something that has happened recently,

Any thoughts would be appreciated.

trusty220, I am in County Cavan, Ireland

July 25, 2022 at 3:47 pm #39521 trusty220Keymaster

trusty220KeymasterWhen I need new linings on the Trusty clutch shoes I use our local Truckstop branch- they send them away and get them re-lined with new material, but beware! If your shoes have rubber buffers on the floating end or rubber bushes on the fixed end they need to be removed before sending them off, otherwise they will come back melted. I did it once with some Trusty shoes and I think they must put them in an oven to cure the adhesive that the linings are attached with because they were very burnt and unusable when they came back- I had to make some new ones.

Definitely replace both springs together as well and you will notice quite a difference straightaway. Don’t be tempted to keep using the triple- our council operators used to keep going with broken springs and very soon afterwards the gear selector ring for forward and reverse gear used to shed it’s teeth inside the gearbox. The fastest I did that job was eight hours and I had all of the lifting gear, so be warned!

Well done for getting it off, though. I only asked where you were from in case you were local to me in Redditch and I’d come over and lend a hand.

July 25, 2022 at 6:34 pm #39526 wristpinParticipant

wristpinParticipantThat’s progress. As Trusty has suggested, having the shoes relined is the way to go. Back in the day we used to get the shoes from all our commercial vehicle units and trailers relined and it was a 24 hour service . Not familiar with your side of the water but there’s plenty of heavy transport, construction, forestry and wind farms etc, that must generate a need for a reclining service. Also, for those springs, there will be a Ransomes distributor, maybe one north and one south. Try them first.

Edit. Looks like these may be your Ransomes agent.

Broderick Grass Machinery Unit 33A Commercial Way Mallusk Newtownabbey Co. Antrim Nothern Ireland BT364UB-

This reply was modified 2 years, 11 months ago by

wristpin.

wristpin.

July 27, 2022 at 7:54 am #39543smithyb

ParticipantThank you for all the help and advice.

I found a Ransomes agent near Dublin which is the closest for me. Parts come from the UK but I can collect them easily from their shop. They can also arrange the repair of the lining. A good find I think.

I go on holidays for 2 weeks tomorrow so this job has to be postponed until I return.

I’ll put up a post when it’s back together and fingers crossed it will all work out.

September 17, 2022 at 1:09 pm #39965smithyb

ParticipantRelined and springs replaced. Now working perfectly.

Plenty of grease applied and it shouldn’t seize again.

Thank you for all the guidance, much appreciated. -

This reply was modified 2 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.